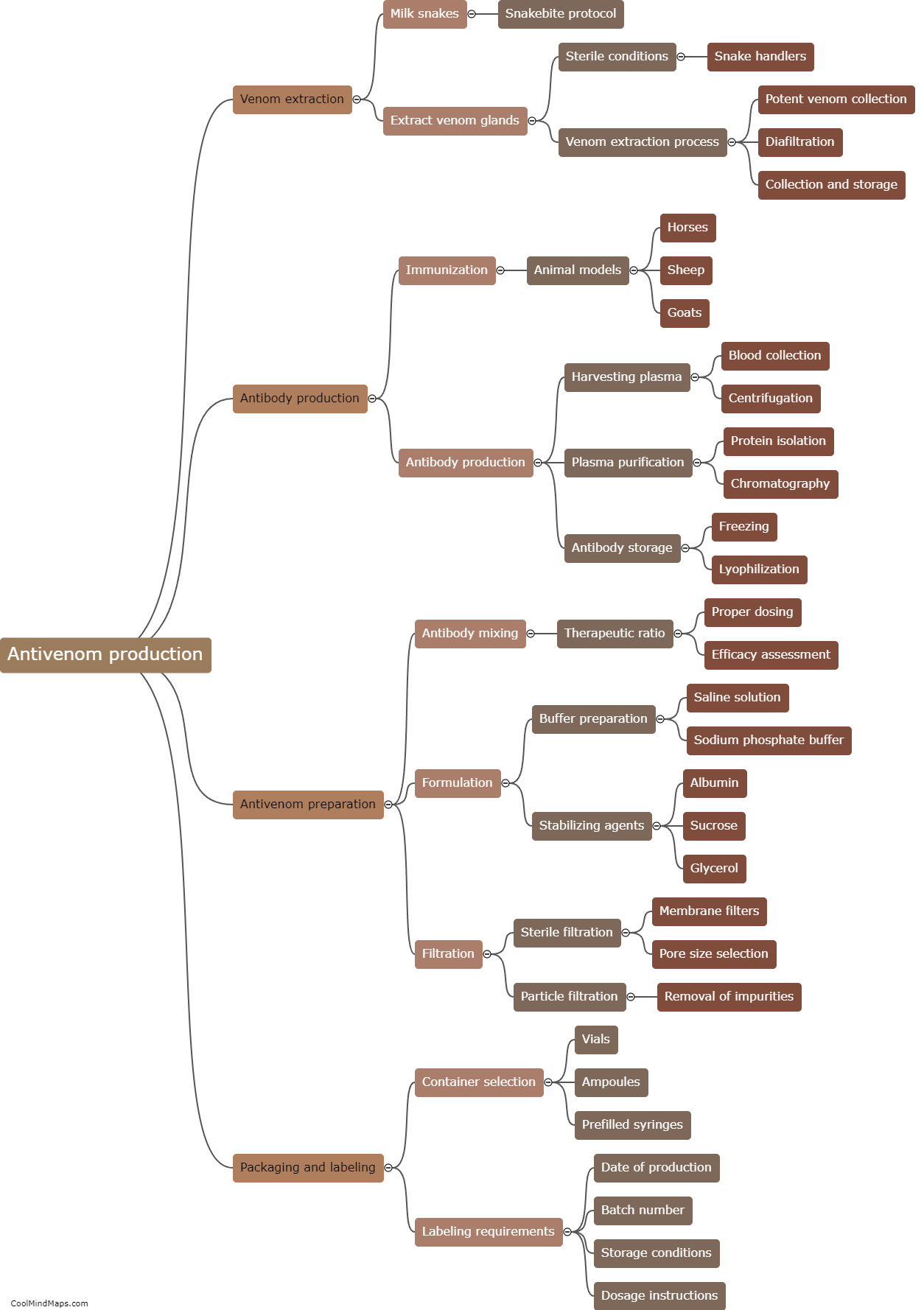

How is antivenom produced?

Antivenom is produced through a labor-intensive process that involves extracting venom from venomous snakes or insects. First, the venom is collected under controlled conditions, ensuring the safety of handlers. This venom is then injected into animals, typically horses or sheep, in small quantities. Over a period of time, the animals develop antibodies against the venom, which are extracted from their blood. These antibodies are purified and undergo several tests and quality control measures to ensure their safety and efficacy. Finally, the purified antibodies are formulated into antivenom, which can be used to treat snakebites or insect stings, neutralizing the venom's toxins and saving lives. This intricate process requires expertise, careful quality control, and adherence to strict guidelines to produce safe and effective antivenom.

This mind map was published on 19 December 2023 and has been viewed 72 times.